what causes a diesel engine to turnover but not start

After a expert run, you shut down the engine for the solar day and settle into a overnice anchorage. The following morning time, cup of java in hand, y'all press the start push and the engine won't start.

If I were the unlucky skipper, I'd repeat the process. Assuming no imminent danger, I am better off if information technology all the same won't offset, because if it does somewhen start, I'm likely facing an intermittent problem, one that will be far more hard to solve with an engine that does kickoff. The situation tin can be divided into 2 basic scenarios: The engine will not crank at all, or it cranks, merely will not offset.

Engine Will Non Creepo

Before doing any troubleshooting, cheque the shift lever position. Many boats have a safety machinery to prevent starting the engine while in gear. Move the lever in and out of gear a few times and attempt again. If the engine still doesn't start, the neutral condom may have failed, and it might be necessary to temporarily bypass this switch to get the engine started.

Bold that the shift lever was non the problem, get-go the troubleshooting with the start battery, battery switch, and ignition circuit breaker. First check the voltage of the battery, either at the main console or with a multimeter at the battery posts. Yous might be able to eliminate a host of possible causes by checking for voltage at the starter solenoid. The solenoid has two larger terminals (see "Shake Easily With Solenoids," October 2014). The wire from the battery connects to 1 terminal, and the other final sends current to the starter. While your partner tries to start the engine, test for voltage on the terminal continued to the starter with the positive meter probe on this concluding and the negative probe on the engine cake (make certain yous have a good connection—preferably find an unpainted bolt or scratch through the paint). The voltage volition fall into one of the three post-obit categories.

If the voltage reads "0" the trouble is somewhere between the bombardment and the solenoid, including the ignition switch circuit and the solenoid itself. Check voltage at the battery posts and if y'all discover good voltage there the trouble lies between the bombardment switch and the start solenoid or in the solenoid. Make sure the battery switch and the ignition circuit billow are in the on position. If yes, then refer to Milk shake Hands With Solenoids column to troubleshoot and do a work-around.

If the voltage reads between 0 and about 8 volts, the problem is either the battery or the starter itself. Cheque voltage at the kickoff battery (while cranking). If it'southward between 0 and 8 volts, you lot have a battery problem. Start the engine from an alternate battery, or outset the generator and brand sure the charger is working. Some boats have a parallel switch for engine starting. If y'all have the option to select an alternate battery, that is a meliorate arroyo than using the parallel switch. Hither's why: If the kickoff bombardment has a bad prison cell, when you parallel with a skilful bombardment you lot weaken the healthy battery. Parallel switches work well when you have a healthy bombardment that is low, only non when the battery has a severe problem. Boaters often underestimate the status of a battery based on the voltage. Go along in mind that at 12 volts a bombardment has about 50 percent of its capacity remaining, and at eleven.5 volts only almost 10 percentage remains.

If the battery has good voltage (12 volts or more than) the trouble likely will exist at the starter. Examine all wiring connections, particularly at the starter. If you lot find rust or corrosion, plough off the battery switch and remove and clean the terminals. If the terminals await proficient, effort tapping the starter with a phenolic hammer or the wooden end of a metallic hammer while cranking.

This practice should only be attempted on older Bendix type starters. On the newer planetary gear starter motors tapping might harm the internal magnets and therefore should be avoided.

If information technology reads more than about eight and less than well-nigh 10, it is likely that the starter or the engine has seized or you have excessive resistance in the starting circuit from poor connections, or resistance inside the solenoid. See above for steps to effort related to the starter. If the engine is seized, you either have an internal failure (game over), or the engine has one or more than cylinders filled with h2o, known every bit a hydro-lock. The pistons and cylinders compress air to generate rut, simply h2o cannot exist compressed and the piston stops one time information technology comes up confronting the liquid, preventing the engine from turning over (and sometimes bending connecting rods in the process).

Water can work its way into the cylinders several ways. With the engine shut downwardly, moving ridge action can force water into the frazzle discharge and up the hose until it fills the muffler. One time that happens the hose will begin to make full and the water level volition start to rise on the exhaust hose leading from the engine to the muffler. In some configurations it is possible for the water to rise loftier plenty to spill into the exhaust elbow and from there into the cylinder through an open exhaust valve. On some engine installations water tin can siphon from the seawater supply, filling the muffler from the opposite side of the exhaust discharge, with the same issue. Finally, water can make full a cylinder from over-cranking a non-starting engine. Every fourth dimension you creepo the starter the engine's raw-water pump turns and pumps water into the cooling circuit, which eventually falls into the muffler. When the engine starts, exhaust gas forces the backlog water out of the muffler. Simply if the engine falls to offset, the water can fill the muffler, eventually filling the exhaust as described earlier. That's why Nigel Calder says, "If the engine doesn't start, finish cranking and start thinking!"

Depending upon your engine and your mechanical skills, you might be able to overcome a hydro-locked engine, but for virtually of us it's time to call a professional.

Engine Cranks, But Will Not Start

Permit's presume that the engine cranks with its usual vigor, only will not start. Use circumspection when cranking your engine, because prolonged attempts or also many of them can lead to issues. Each try should last no longer than 5 to 10 seconds, and pause virtually 15 seconds between attempts. Every time you crank, a tremendous amount of current flows into the starting time excursion, and excessive cranking will create high temperatures that can damage components. As for the number of attempts, you want to avoid hydro-locking the engines every bit discussed earlier.

No rule of thumb determines the safe threshold, due to the diverseness of configurations. If the engine has non started after several attempts, yous tin close the raw-water intake seacock, but you must be prepared to open it immediately if the engine starts, otherwise you lot may ruin the impeller.

Diesel engines used to need 3 things to run: air, fuel, and compression. At present a fourth chemical element has been added: a properly working engine computer or ECU.

If your engine ran yesterday, chances are that air is not a problem (clogged filter, blocked exhaust). If it has been running well (not smoking, starting reliably), then compression will not be a likely suspect. That leaves us with fuel and (on newer engines) the estimator.

Fuel problems might be simple. Perhaps yous changed a filter and left a supply valve closed, pinched an O-ring, or inadvertently bumped against a valve handle and cutting off the supply. Inspect valve positions at the tanks and filters get-go. Await at the fuel level inside the primary filters to see if they are total. A chock-full chief or secondary fuel filter falls low on the list of possibilities. This status usually occurs gradually, and on the previous 24-hour interval'due south run loftier vacuum pressure would take been noted on the primary filter. A clogged principal or secondary filter would eventually limit engine rpm during the run, not suddenly overnight. If you lot recently changed the fuel filter, it is possible y'all introduced air into the system. On older engines the air can prevent the engine from starting, but on most engines the cranking process will forcefulness the air out. If these areas check out okay, it's time to have a look at the engine.

Most marine diesels use a solenoid to close down the engine. They normally remain open, allowing fuel to flow. When you press the Cease button, current flows to the solenoid, endmost the valve and cutting off the supply of fuel (in some cases, the current holds the valve open while the engine runs). These valves tin fail and when that happens, no fuel can menstruation.

If you are familiar with this solenoid on your engine, you tin often visually confirm that it functions properly. Your engine manual likely shows the location and role of this solenoid.

You lot tin rapidly dominion out fuel issues by checking the render line. Remove the return line at the tank and hold the cease over a cup while someone cranks the engine. If fuel is coming through, so the engine is getting enough fuel to run.

Starting Fluids

Given our assumption that the engine has been starting easily and running well, issues related to pinch and air supply would exist longshots. Using starting fluid on a diesel engine should be avoided. Y'all might void the warranty or damage the engine. If your engine has glow plugs, ether-based fluids can ignite and cause harm. Ether combusts at a lower temperature than diesel, and that means it will ignite before the piston reaches the finish of the pinch stroke, throwing off the timing of the combustion cycle. Additionally, the starting fluid washes the oil off of the cylinder walls, leaving them dry out during start-up, which accelerates wear.

If all else has failed and you must become the engine running, you lot can try spraying a small amount of WD40 into the air intake. WD40 contains enough lubricant to protect the cylinder walls and is less volatile than ether. Silicon spray lubricant works well in this application every bit well. Remember nonetheless, that an engine under warranty might be jeopardized. Use of any aerosol every bit a starting fluid should be a terminal resort. If the engine starts briefly then quickly dies, you probably have a fuel delivery problem.

The ECU

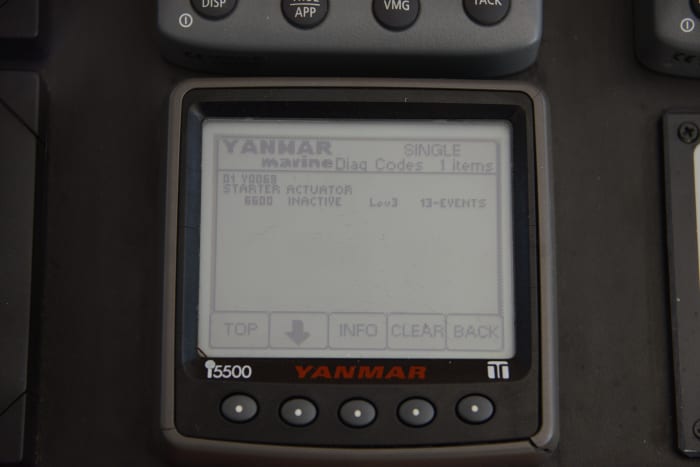

On newer engines (the year varies with horsepower range and manufacturer), a small computer (or ECU) controls its operation. A failed ECU—or a failed connector leading to the ECU—can forbid an engine from starting. In some cases the digital instrument panel at the helm gives you access to mistake codes. If you lot are lucky, the lawmaking reference tin can be found in the engine manual. In many cases the error code numbers are generic and can exist found online. If the ECU has failed, you lot will simply need one tool—your cellphone—and the number of the local tow company.

Want to learn more about Maintaining and Troubleshooting Diesel Engines? Cheque out the Marine Diesel Maintenance & Troubleshooting Form over at Boaters University, our online education platform. Utilize promotional code PASSAGEMAKER to save 20%.

Source: https://www.passagemaker.com/technical/troubleshooter-what-to-do-when-your-engine-wont-start-and-it-started-yesterday

0 Response to "what causes a diesel engine to turnover but not start"

Post a Comment